Cambridge DT Partners For Reverse Engineering

Our friends at Cambridge Design Technology have published the following article on reverse engineering.

Link to original article:- Cambridge Design Technology

What Is Reverse Engineering?

Reverse engineering is the process of analysing an existing product’s constituent components to allow a fully replicated design – or design knowledge – to be created from the information extracted.

Products and concepts as wide-ranging in structure and function as mechanical devices, electronic components, computer software, chemical formulas or organic matter are all suitable for analysis using RE techniques.

In practical terms, a typical reverse engineering project will involve working backwards from a chosen product to determine the design and technology used by the product’s creator. This accrued data then allows those applying RE to reproduce or refine the product – or simply to put the information to use in the concept development of a companion or related product.

Why Would You Need Reverse Engineering?

In today’s fast-paced business environment, existing mature life cycle products may require reverse engineering for:

- Compliance or revalidation processes

- Converting design drawings into 3D digital data.

- Recovering data and designs lost during company transition, data corruption or IT failures

- Product Improvement

Whatever the need, reverse engineering can shine a light on the processes involved in the creation of the product in question – whether this is to establish details of an existing technologies or an unusual device, or simply to determine technical aspects of an established product that may not have been manufactured for some time.

Product Improvement

Product improvement can be a significant driver in wanting to RE a product.

- Reducing manufacturing cost

- Refining product performance

- Replacement of a product

Designers and engineers are always looking for ways to improve both novel concepts and existing products. RE can provide the data and knowledge required to refine and improve a product’s assembly process and working capabilities.

By simplifying a product’s manufacture, its cost can potentially be reduced and its performance improved. The information provided by reverse engineering can even give designers and engineers the necessary spark to create an alternate version of a product.

How Do You Reverse Engineer?

The basic goal of reverse engineering is to develop an understanding of a product and its parts by applying in depth analysis. Once these factors are understood, the engineer can begin to crystallise the original design intent of the working parts, their critical tolerances, materials used and key functions within the assembly.

Design Intent Capture

The design team will start by measuring components using digital, traditional and sometimes non-contact methods to define the parts. These parts are then modelled up using 3D CAD.

Once the parts have been made and the 3D assembly is created, the models may be proofed and tested. Although in some instances absolute accuracy in the RE process is crucial, some RE projects will require the design to be improved at the same time. Detailed understanding of a design can sometimes lead to the reducing of accuracy, in less critical areas, allowing potential cost savings in manufacture.

There is a technical risk to every design exercise. In RE, a seemingly minor measurement error involving as little as a fraction of a millimetre can potentially have a major and negative effect on the assembly process, so checking and proof reading of specifications and prototyping can be essential.

There are several tools within the CAD environment to achieve accurate design capture:

- Interference checking to ensure the parts can operate with sufficient clearance or are purposely interfering (such as self-tapping screws etc)

- Wall thickness analyses to ensure that (for example) a moulding has not been modelled with excess wall thickness which would potentially cause problems in moulding further down the line

- Draft analyses, again with moulded components to ensure that all surfaces have been correctly drafted in the right direction. This also helps to validate the split lines of the product.

- Surface analysis methods such as “Zebra Striping” can be employed to visualize curvature on smooth surfaces and evaluate the quality of surfaces created.

- Other CAD tools that aid the process look at part volume, mass properties and undercut checking to help ensure the products parts are robust.

These various methods can all be employed to develop and streamline modern manufacturing techniques, processes and material usage. With design excellence being a foremost principle of the exercise, the elimination of parts due to their redundancy or obsolescence are as important as the introduction of new parts and features that will enhance the product.

How Do You Reverse Engineer A Very Complex Shape?

CDT’s design team had their reverse engineering skills challenged when Hornby Hobbies asked us to reverse engineer various shapes of their classic Grand Prix racing cars. This involved detailed research and recreation of car body shapes using various measurement methods, photographs, artistic licence- as well as assessing design features by eye.

Reverse engineering projects like this can be costly and time-consuming – but the results can be spectacular. Even the smallest detail, such as the beautiful lines of a full-scale racing car are reduced to exquisite, 1/32nd scale replica slot cars. A stunning showcase of reverse engineering’s versatility and almost unlimited scope.

There Is An Alternative – 3D Scanning

Images supplied courtesy of CDG & Shining 3D

The accuracy of modern scanning is down to fractions of a millimetre even on large scale dimensions. And when large, organic shapes require ultimate accuracy to be taken from the original, then the extraordinary precision of 3D scanning can be harnessed to great effect.

By taking multiple scans of an object from all possible directions and viewpoints, the 3D scanner collects geometric data that is combined using a common reference system. From the extrapolated data, a digital 3D model can then be constructed.

3D scanning is a diverse technique, used broadly across many industries. Objects as large as ships, aeroplanes and even entire buildings have been successfully scanned. At the opposite end of the scale, minute, intricately-detailed objects such as dental devices, coins and skin textures have been successfully captured.

It’s a technique that excels in scanning tangibles, yet can also be used to create intangible designs such as 3D animations and special effects.

3D Scanning applications include:

- reverse engineering into CAD

- data input for digital modelling or editing

- measuring and inspecting parts

- data achieving

- virtual reality

3D Scanning partnership: working with Concurrent Design Group

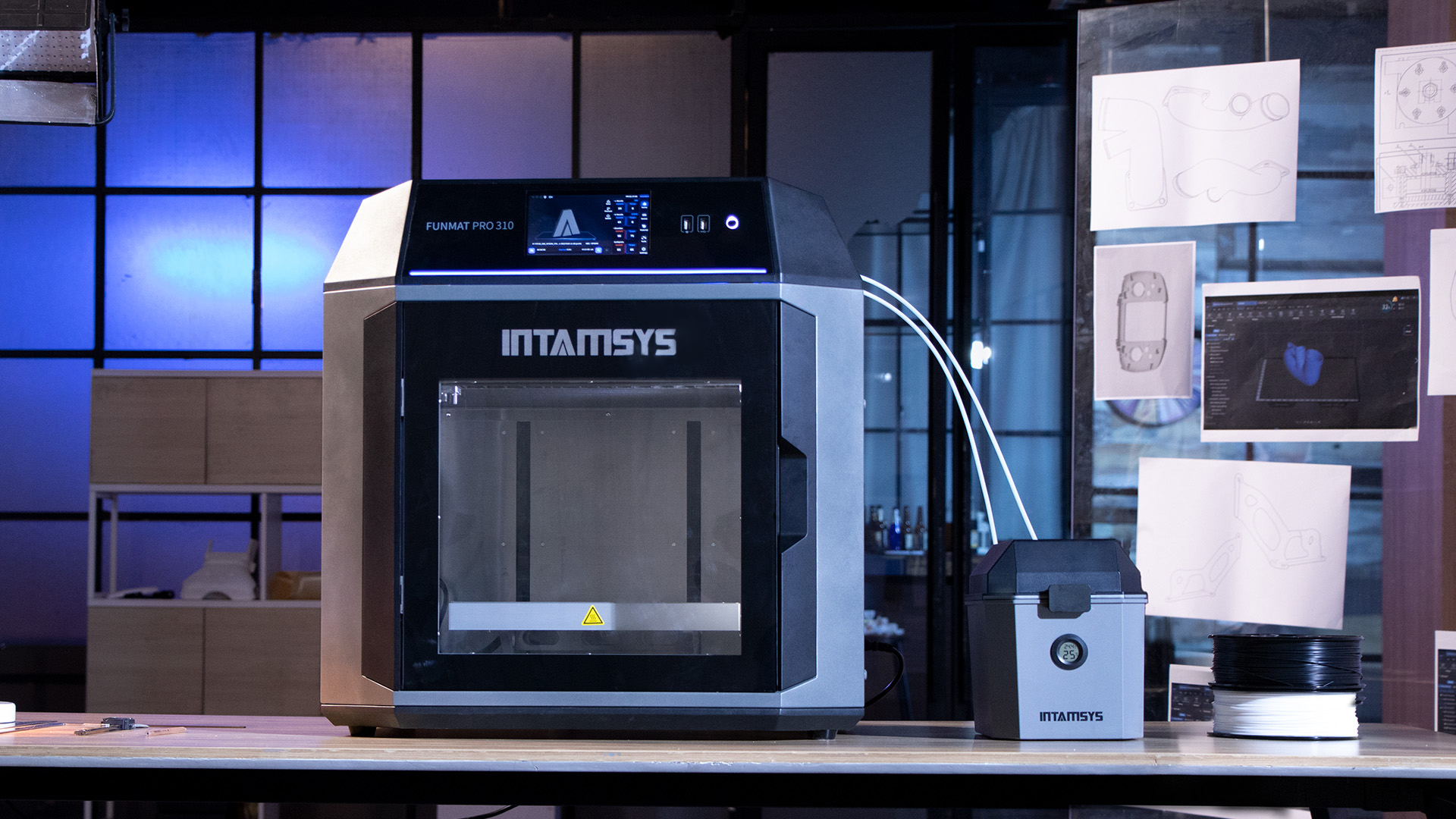

We have been working with 3D scanning experts Concurrent Design Group (CDG) for many years now. In fact, we bought our first 3D printer from CDG. They have been at the cutting edge of 3D engineering design technology since 1993 and, given their vast experience and knowledge in this field, they are Cambridge Design Technology’s preferred supplier of 3D scanning.

Realise Your Vision

If your company has ideas that require cutting-edge design, technology and engineering input, Cambridge Design Technology have the knowledge, experience and creative energy to help you realise your vision – including a full Reverse Engineering and 3D Scanning service.