ComplexaHPE Streamlines Medical Mould Design with Cimatron CADCAM

Precision UK Mouldmaker ComplexaHPE Drives Medical Tooling Innovation with Cimatron CADCAM software Established in 2021 by Managing Director Paul McHugh, ComplexaHPE was created as a

3D Systems have released a new materials – the Figure 4 F3 Orange is a prototyping plastic material specifically engineered for Figure 4, offering a cost-effective solution for producing high-quality parts with excellent mechanical stability. It is a rigid, general-purpose material suitable for a wide range of applications, including form, fit, and functional testing, as well as the fabrication of fine-detail components, jigs, fixtures, and assemblies.

With fast print speeds and high-resolution colour output, it delivers superior visual detail and smooth surface finishes, making it an ideal choice for efficient and accurate prototyping across a wide range of use cases.

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. In addition, properties such as flammability, dielectric properties, and 24 hour water absorption are provided. This allows for better understanding of the material capability to aid in design decisions for the material. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Solid material properties reported were printed along X-axis.

Precision UK Mouldmaker ComplexaHPE Drives Medical Tooling Innovation with Cimatron CADCAM software Established in 2021 by Managing Director Paul McHugh, ComplexaHPE was created as a

FIGURE 4 F3 ORANGE DELIVERS HIGH RESOLUTION, FOR RAPID PROTOTYPE PARTS. 3D Systems have released a new materials – the Figure 4 F3 Orange is

Culinary Concepts & the story of the Brass Crab When a Crab, a 3D Scanner and a 3D Printer come together to create a replica

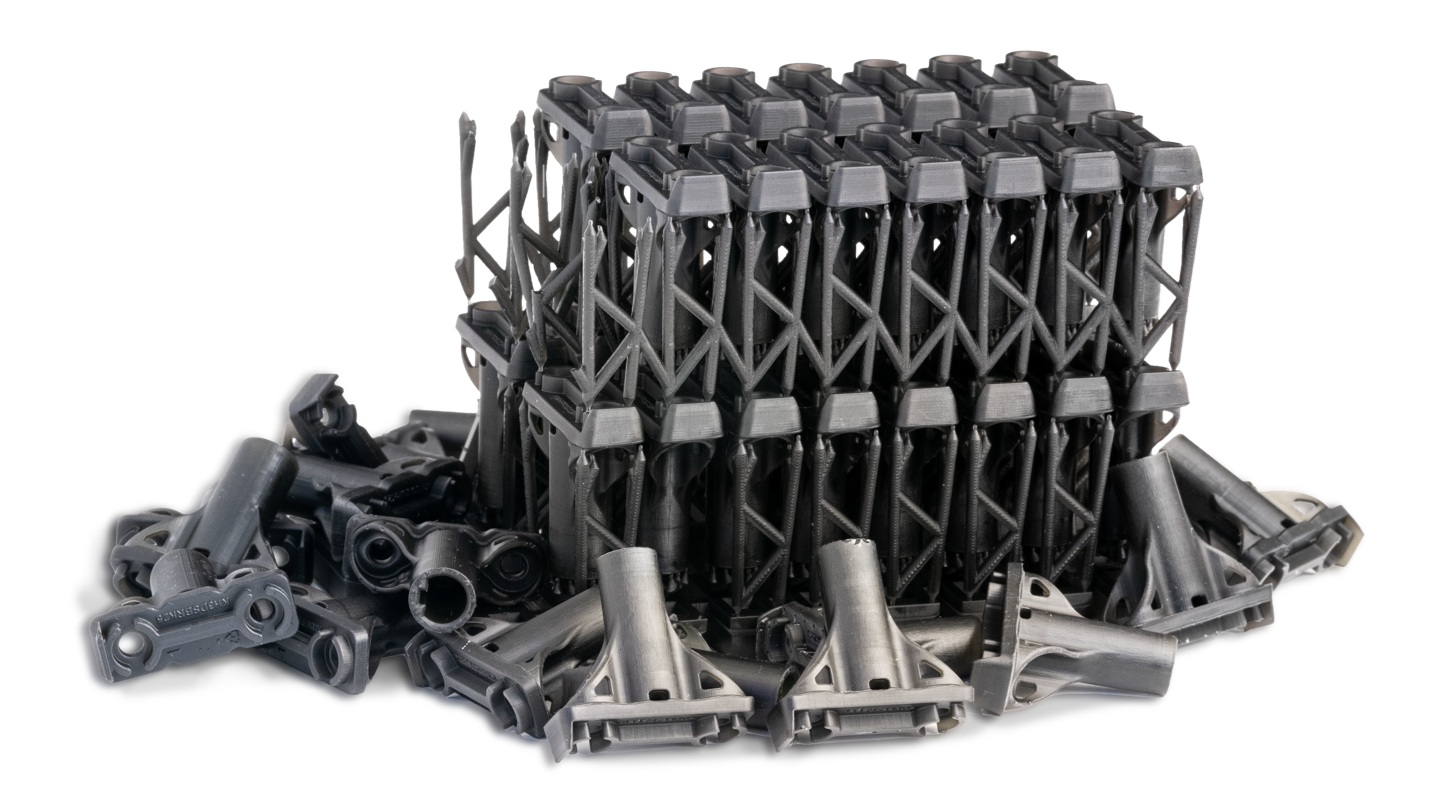

BATCH 3D PRINTING In order to print in batches you need a fully reliable printer which can handle printing multiple parts at once. You also

Rapid 3D Scan of a Railway Stop Buffer in Derby 3D Scanning with the FreeScan Trak Pro Nova and Geomagic software Scanning large objects with