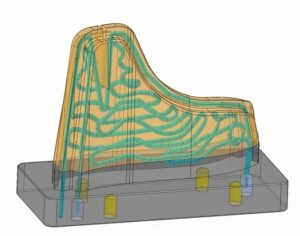

Cimatron Conformal Cooling package for toolmakers, mould designers and injection moulding companies. The fastest way to create complex waterways, suitable for metal 3D printing.

| Technology | CADCAM, Tool Design |

| Manufacturer | Cambrio |

| Licence types | Dongle, Network |

| Attributes | Conformal Cooling design |

Conformal cooling can benefit all types of molded parts, especially complex parts. However, you do not necessarily need to 3D print your entire mold—the key is to detect the areas that would benefit from conformal cooling and use AM only for those areas.

The primary issue with traditional cooling methods is that they can’t reach the places where cooling channels are needed. Conformal cooling has the most significant effect on injection molds that are experiencing problems with warpage during production because of irregularities or imbalances in the cooling process.

With the right tools, producing conformally-cooled inserts to address key problem areas in the mold is straightforward and very effective.

Cimatron includes a new optimized curvature function that highlights areas where a cooling channel cannot be created, such as a curve radius smaller than the channel diameter, providing the user with point-and-click controls to correct the channel path.

To view more Cimatron products, click here

If you want more information, please download the E-book on the below.