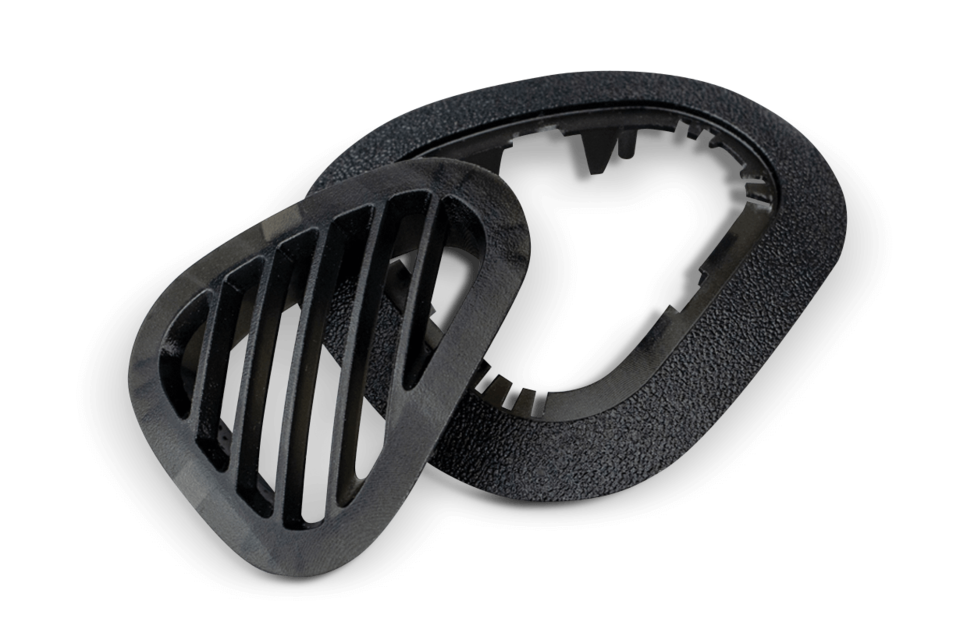

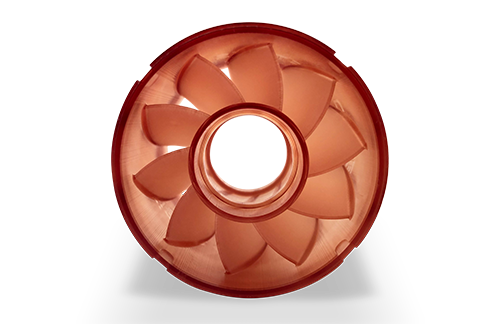

Modular Scalability

The base configuration of Figure 4 Modular is comprised of a single printer and a central controller. This can be easily scaled to up to 24 printer modules on a single controller, with layout configuration flexibility, empowering production to rapidly multiply without disruption to the shop floor.

![Figure 4 Modular Set [Ex-demo]](https://cdg.uk.com/wp-content/uploads/2020/06/Figure-4-Modular-printer.jpg)

![Figure 4 Modular Set [Ex-demo] - Image 2](https://cdg.uk.com/wp-content/uploads/2021/02/3d-systems-figure-4-rigid-white-inline-enclosure-full-stack-transparent-300ppi.png)

![Figure 4 Modular Set [Ex-demo] - Image 5](https://cdg.uk.com/wp-content/uploads/2018/07/figure-4-parts.jpg)