3D Printed Scoliosis Braces Transforming Modern Orthotic Care

3D Printed Scoliosis Braces Transforming Modern Orthotic Care Scoliosis is a spinal condition defined by an abnormal sideways curvature of the spine, often developing during

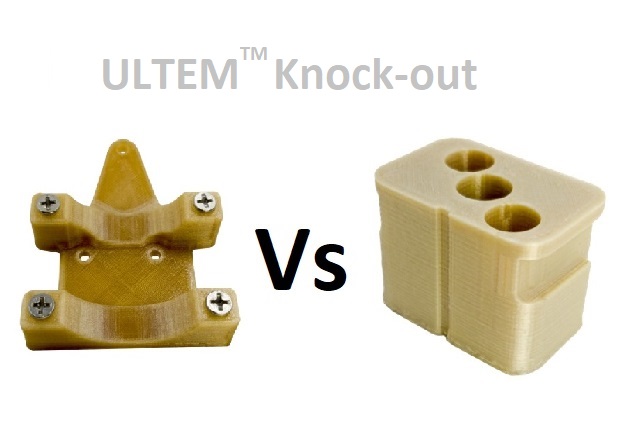

The ULTEM™ resin family of amorphous thermoplastic PEI (polyetherimide) materials offers outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance. ULTEM materials uniquely balance both mechanical properties and processability, offering design engineers exceptional flexibility and freedom.

Ultem 1010 and Ultem 9085 are grades of 3D Printer filament. They are widely used in the Aerospace, Automotive, Defence, Transportation and Electronics industries.

| ULTEM 1010 | Material | ULTEM 9085 |

| Amorphous | Structure | Amorphous |

| Flame Retardant | Flamability | Low FST (flame, smoke, toxicity) |

| 190°C | HDT (heat deflection temp) | 152 °C |

| 217 °C | Tg (glass transition temp) | 186 °C |

| 89.8 Mpa | Tensile Strength | 76.7 MPa |

| 167.2 Mpa | Flexural Strength | 137.8 MPa |

| High | Chemical Resistance | High long-term |

| Funmat Pro 610 HT

220 °C chamber temp |

Recommended 3D Printer (approved for Ultem) | Funmat Pro 610 HT

180 °C chamber temp |

| Intamsys, 3DXTech | Recommended Ultem filament suppliers | Intamsys, 3DXTech |

| Intamsys SP5080 | Recommended Support material | Intamsys SP5040 |

ULTEM™ is a trademark of SABIC Innovative Plastics, Inc. | SHPP GLOBAL TECHNOLOGIES B.V.

3D Printed Scoliosis Braces Transforming Modern Orthotic Care Scoliosis is a spinal condition defined by an abnormal sideways curvature of the spine, often developing during

Touch™ Haptic Arm is a mid-range, professional haptic device used in research, 3D modelling and OEM applications Touch is a motorized device that applies force

3D Systems announce MJP 300W Plus wax 3D Printer as the new GOLD Standard for investment casting wax models. Premium quality, speed and efficiency The

INTAMSYS Launches the FUNMAT PRO 310 APOLLO: Redefining Continuous Production with High-Speed, High-Strength PEEK & PAEK 3D Printing Over the past decade, FFF 3D printing

Culinary Concepts & the story of the Brass Crab When a Crab, a 3D Scanner and a 3D Printer come together to create a replica