3D Systems signs CDG as Figure 4 135 Exclusive partner

3D Systems have confirmed CDG 3D TECH as their exclusive partner for the UK & Ireland for the Figure 4 135 DLP 3D Printer; this

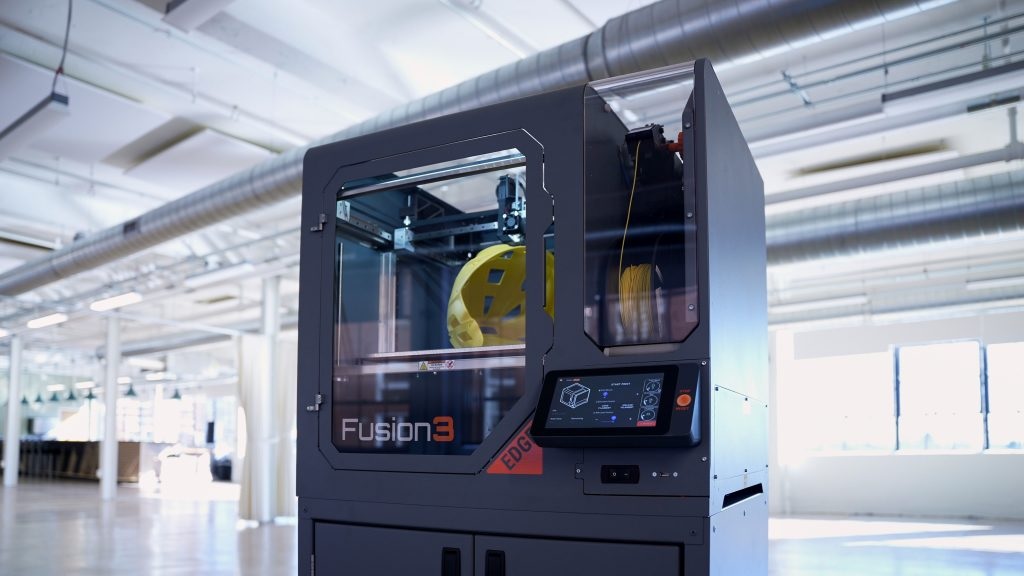

3D printer manufacturer Fusion3 has announced the launch of its new EDGE 3D printer.

Fusion3’s patent-pending ANVIL print head system combines precision milled print head components with an inexpensive surgical steel print tube used in place of the traditional screw-in 3D printer nozzle. The ANVIL print head components are precision milled, and utilize a high-quality, high-temperature heater cartridge and a PT-1000 temperature sensor. Use of the single surgical steel print tube, enables faster 3D printing and is wear-resistant for use with abrasive filaments such as carbon fiber or fiberglass-reinforced filament. In addition, the single tube design is more reliable, eliminating the chance of leakage found in a traditional screw-in nozzle print head, and inexpensive and easy to replace, translating to lower operating cost.

Build volume 355 x 355 x 365mm

Print speed Up to 200mm/s

Max nozzle temp 320°C

Max bed temp 145°C

Max chamber temp 70°C

Touchscreen 7″

3D Systems have confirmed CDG 3D TECH as their exclusive partner for the UK & Ireland for the Figure 4 135 DLP 3D Printer; this

CDG 3D TECH open their new Additive Manufacturing Centre in Basingstoke on 1st May 2025. This new site is to be focused on:- Showroom for

Transforming Sign Making with the Piocreat K8 Channel Letter 3D Printer In the fast-paced world of visual marketing and signage, customisation and speed are everything.

PostProcess Technologies Unveils – DEMI X 200 Plus – Compact All-in-One Post-Processing System We are excited to introduce the new PostProcess desktop DEMI X 200 Plus,

Introducing SUZY, our newest SLS 3D printer, designed specifically for small-scale production and prototyping.

Experience cutting-edge technology that delivers speed, efficiency, and outstanding print quality – all in one powerful machine.