CDG 3D Scanning Open Days – 1st & 3rd July 2025 – Free Tickets

Discover the latest 3D Scanning Technology at CDG 3D TECH Open Days CDG 3D TECH, together with our partners Shining3D and Geomagic, are presenting two

Evatronix has joined Universal Robots ecosystem and now has a UR+ certificate for its Heavy Duty Optima 3D scanner as a device fully compatible with UR cobots. The co-operation between companies has been established to improve the process of deploying automated quality control systems on production lines.

UR+ certificate (a platform offering certified accessories for Universal Robots cobots) guarantees seamless implementation of the system, which reduces the time of return on investment.

The new eviXscan FinePrecision 3D scanner is primarily intended for high-precision small part scanning. As such, the device is well suited to the needs of watchmakers, jewellery and medical professionals, for example those involved with prosthetics and implants.

In addition, the FinePrecision scanner will see extensive use in quality control and predictive maintenance applications, whereby production equipment can be scanned to identify early-stage microdamage.

Kamil Góra, Product Manager of 3D Scanners at Evatronix, states, “Based on feedback from our Heavy Duty scanners and discussions with our customers indicating areas where precise measurement and very detailed surface mapping was needed, we defined the requirements for a scanner that is a solution for these unfulfilled needs. According to these requirements, our R&D department developed a product ready to face the everyday challenges of metrology labs measuring fine mechanical objects.”

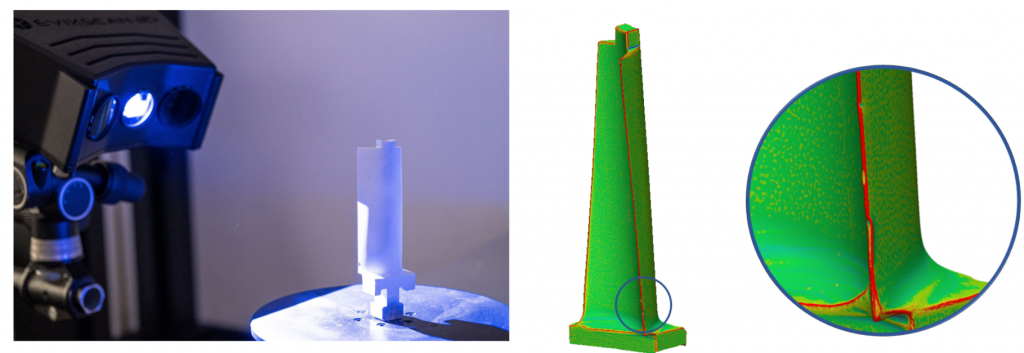

Fine Precision 3D scanner

The Evatronix eviXscan range already comprises a number of stationary desktop 3D scanners suitable for engineering applications. The high-performance Heavy Duty Quadro boasts a scanning accuracy of 0.013m and offers four 5MPix cameras. With a dust-proof IP62 rating, the device is designed to be used in a whole host of harsh environments on the shop floor.

Similarly, the Heavy Duty Optima is intended for reverse engineering, contactless quality control, and rapid prototyping applications with a wide measuring range of 250 x 170 x 120mm. With two 5Mpix cameras and a blue LED light engine, the machine grants users a measuring accuracy of up to 0.0183mm.

The scanner operates on the company’s blue light LED technology, and comes complete with two high-speed 8.9 Mpix cameras. With an accuracy of up to 6 microns and a repeatability of within 3 microns, the system is capable of reliably reproducing complex mechanical components. This precision can be attributed to the scanner’s excellent point density, which clocks in at more than 1200 points per square millimeter, resulting in a scan resolution of just 28 microns.

There is also something to be said about the device’s scan speeds. Since the cameras trigger every time a new pattern is detected from the light projection system, each scan cycle is completed in less than one second. To ensure the scanning workflow is as streamlined as possible, the standard FinePrecision set includes a rotary table (20kg max weight), a tripod, an A5 calibration table, a transport box, and marker frames to assist with folding scans.

Góra adds, “Using cameras and a projector optimized specifically for our scanner, we are able to offer a product adjusted to the needs of our users. This is a scanner for engineers, from engineers.”

Technical Specification

Below are the technical specifications for the eviXscan FinePrecision 3D scanner:-

| Field of View | 120 x 60 x 45mm |

| Accuracy from | 6 microns |

| Measurement repeatability | 3 microns |

| Working distance | 186mm |

| Scan resolution | 28 microns |

| Point density | 1233 pt/mm² |

| Cameras | 2 x 8.9MPix |

| Light source | Blue LED |

| Weight | 5.05kg |

| Dimensions | 233 x 294 x 105mm |

Discover the latest 3D Scanning Technology at CDG 3D TECH Open Days CDG 3D TECH, together with our partners Shining3D and Geomagic, are presenting two

CDG 3D TECH open their new Additive Manufacturing Centre in Basingstoke on 1st May 2025. This new site is to be focused on:- Showroom for

Transforming Sign Making with the Piocreat K8 Channel Letter 3D Printer In the fast-paced world of visual marketing and signage, customisation and speed are everything.

PostProcess Technologies Unveils – DEMI X 200 Plus – Compact All-in-One Post-Processing System We are excited to introduce the new PostProcess desktop DEMI X 200 Plus,

Introducing SUZY, our newest SLS 3D printer, designed specifically for small-scale production and prototyping.

Experience cutting-edge technology that delivers speed, efficiency, and outstanding print quality – all in one powerful machine.