The New Omni PRO and PRO HT 3D Printers Are Ready to Innovate Industrial Applications

It goes without saying that the additive manufacturing sector as a whole is turning toward greater industrialization and has done so for the past few years. A sharp contrast to the technologies’ origins in the 80s, 3D printing is being used in a wide variety of sectors in everything from prototyping to end-use parts. This includes FFF 3D printing, which was confirmed in a report this year by Hubs, to continue to be the most favored 3D printing method among its respondents, a staggering 56% use it compared to the runner-up, SLA at 20%. Now, we have yet another solution entering the market which hopes to push 3D printing even further with the company even claiming that they could be considered “the new standard in the world of 3D printing.” This of course refers to Omni3D’s launch of the Omni PRO and PRO HT 3D printers, which is expected to be at Formnext this year.

We have spoken to you before about Omni3D. The Polish manufacturer is quickly establishing itself in the world of high-temperature and professional FFF 3D printing. Indeed, back in March of this year, in an interview with the CEO, the company noted its commitment to the B2B 3D printing market, explaining that its mission before all is to “provide tools and complete ecosystems to create the most innovative and cost-effective products.” Now with these latest printers, we see that they are seeking to exemplify that goal and will be working as well with some interesting applications in the months to come. Paweł Robak, the CEO of OMNI3D, further expands “Our company has been focused on developing cutting-edge 3D printing technology from the very beginning, and this introduction of a new printer – the Omni PRO and Omni PRO HT – is confirmation of our determination to achieve perfection. The collaboration of our engineering and design teams has led to the creation of a product that meets the highest expectations of our customers.”

The newly launched…

What Can We Expect From the Omni PRO and PRO HT?

But knowing all that, the question still remains: what exactly will Omni3D be showing us with the Omni PRO and PRO HT 3D printers? Both will have a generous build volume of 500 x 500 x 500mm, be compatible with Simplify3D and have a filament diameter of 1.75mm. The minimum layer height as well as some of Omni3D’s common features will also be the same. However, they differ notably in terms of materials. Though the Omni PRO is already used with filaments like PC, PC-CF, PEEK, PEEK-CF and PPA-CF, the Omni PRO HT, as its name suggests, is even more geared toward high-temperature materials including ULTEM 1010 and UTLEM 9085.

Wojciech Wiśniewski, a 3D Printing Technologist who was responsible for testing the machine and compatible filaments at Omni3D, explains, “Chamber temperature is especially important to ensure high mechanical properties of parts printed with engineering and high performance polymers. It helps not only in creating a stronger interlayer bond, but also reduce the internal stresses within the material. Such stresses pose a significant problem in FDM/FFF 3D printing.” As a result, the Omni PRO HT will boast a higher chamber and build plate temperatures. Additionally, the Omni PRO HT will be faster at a max printing speed of 200 mm/s and 86 cm³ /h.

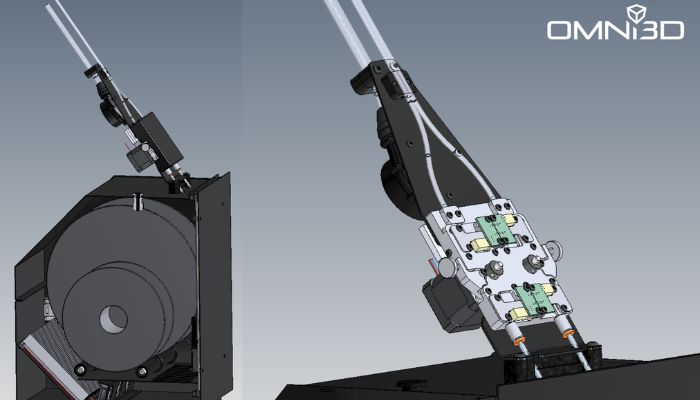

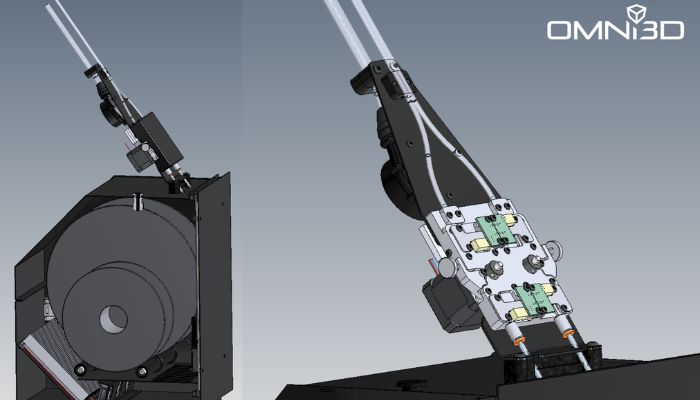

The top of the machine

Beyond that, they both include a number of unique features that Omni3D hopes will help them stand out even more. Moreover, in addition to the large working space, they also feature a cooling system for the extruders, air circulation for great temperature control of the print, the Filament Flow Control™ system and both head leveling and platform auto-leveling. These will allow for a hassle-free experience that will also significantly reduce printing failures for users.

The filament chambers with automatic feeders and heating are also worthy of mention. The Omni PRO and Omni PRO HT both are equipped with two filament chambers which can contain up to two 3 kg spools each, for a total capacity of 12 kg in the printer. Additionally, every spool has its individual smart feeder. Once filament goes through the sensor, it is pushed towards the extruder equipped with a presence and flow sensor. The user is able to choose which to use first, though if it runs out before printing is done, it will automatically switch to the next one. All for a more seamless production experience.

The filament chambers allow up to 4 filament spools in the machine simultaneously

What Are the Applications?

By aiming to push innovation in the industry even further, Omni3D also seems to have lined up a number of interesting clients and applications already. The printers are expected to be particularly useful for sectors like defense, aerospace and railway sectors. “I’m very proud that our systems are well implemented and helps such clients as Airbus, BAE Systems or NAVAL Group who are using them for the most advanced applications in the 3D printing industry,” expanded Pawel Robak.

Though still newly launched, there are a number of interesting applications being seen with the Omni PRO and Omni PRO HT 3D printers

Adam Wilczyński and Piotr Skotarczyk, who were responsible for design of the OmniPRO, concluded, “Our goal with Omni PRO was to build a machine that can meet various user requirements. From our experience with previous Omni printers, we knew that a lot of customers, once they have a 3D printer, try to utilize it in different areas of their business. Therefore, we wanted to design a machine that can flawlessly print from a wide range of materials. However, we focused not only on improving the temperature parameters but also on accuracy, speed, reliability and ergonomics. To achieve this, Omni PRO is built with industrial grade components and has some smart custom features that we as engineers and users find helpful. As a name suggests, Omni PRO is designed for professionals from different industries to help them overcome limitations of traditional production processes, whether it’s prototyping or low-volume production.” You can find out more about the printer on Omni3D’s website HERE or Formnext 2023 where the printer will have its official launch.

*All Photo Credits: Omni3D